EN343 Waterproof Rating Raincoat Supplier | Certified Workwear, Safety Gear & Custom Manufacturing

Why EN343 Raincoats Matter in Today's Market

What Makes EN343 Different From Regular Waterproof Ratings?

EN343 isn’t just another waterproof rating – it’s a comprehensive European standard that addresses both waterproofing and breathability, making it the gold standard for professional workwear. Unlike simple hydrostatic head measurements, EN343 certification ensures that rainwear performs reliably in real-world industrial conditions.

Key Differentiation Factors

- Double Certification: Tests both waterproofing AND breathability

- Industrial Grade: Designed for heavy-duty professional use

- European Compliance: Meets EU PPE regulation requirements

- Multi-Class System: Allows buyers to choose appropriate protection levels

Understanding EN343 Waterproof Ratings

What Is EN343?

EN343 is a European standard that specifies requirements for protective clothing against foul weather. Published by CEN (European Committee for Standardization), this standard has become the benchmark for waterproof and breathable workwear in Europe and increasingly worldwide.

The Two Key Requirements: Waterproofing & Breathability

EN343 uniquely combines two critical performance aspects that traditional ratings often treat separately:

Waterproof Performance (Class 1-3)

Tests resistance to water penetration under pressure, ensuring protection against heavy rain and extended exposure.

Breathability Performance (Class 1-3)

Measures moisture vapor transmission rate, preventing heat stress and maintaining wearer comfort during extended use.

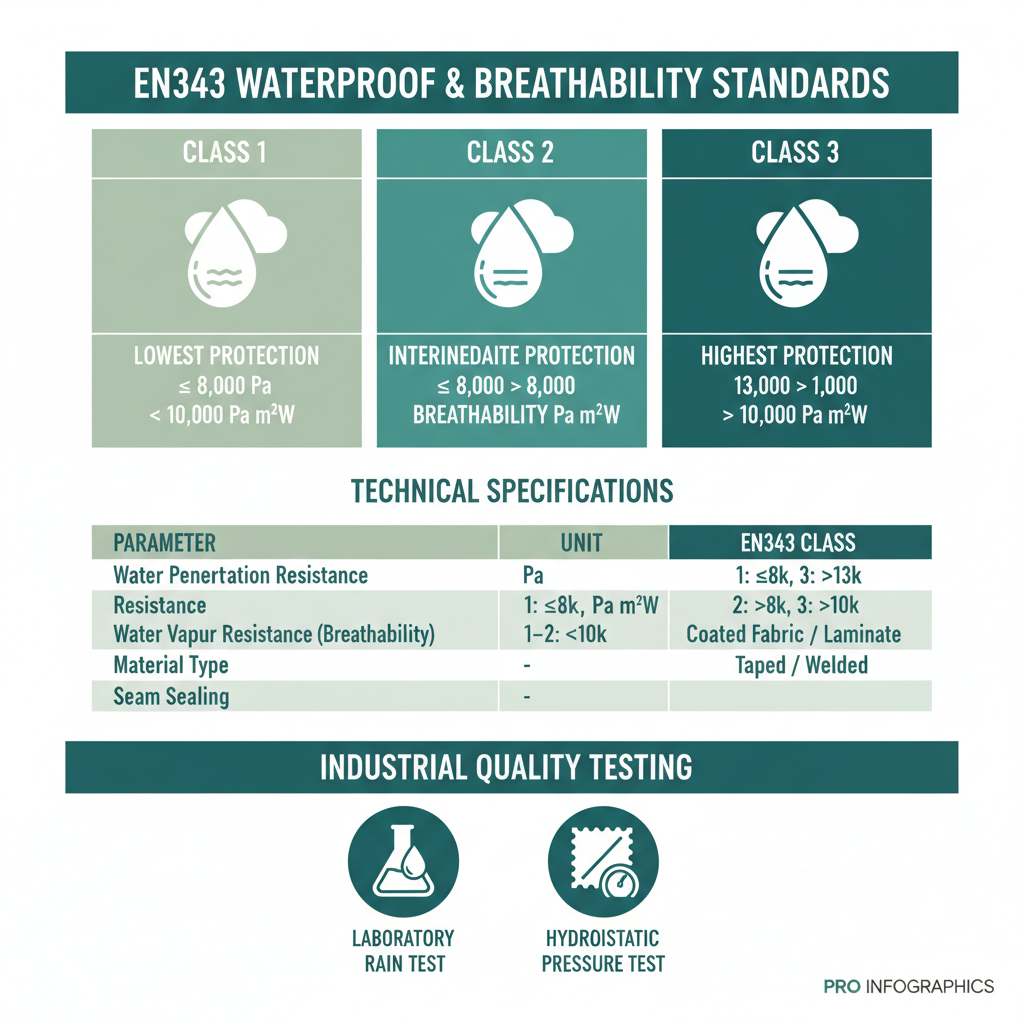

The Meaning of Class 1, Class 2, and Class 3 Ratings

EN343 uses a sophisticated classification system that allows buyers to select appropriate protection levels for their specific applications:

| Class Level | Waterproofing (mm) | Breathability (g/m²/24h) | Typical Applications |

|---|---|---|---|

| Class 1 | 800+ mm | 1,000+ g/m² | Light rain, short exposure |

| Class 2 | 1,300+ mm | 2,000+ g/m² | Moderate rain, extended wear |

| Class 3 | 2,000+ mm | 3,000+ g/m² | Heavy rain, professional use |

EN343 vs. Other Ratings (e.g., HH, WP, Hydrostatic Head)

Understanding how EN343 compares to other waterproof ratings helps buyers make informed decisions:

Hydrostatic Head

Measures only waterproofing pressure. No breathability assessment.

WP (Waterproof)

Varies by manufacturer. No standardized testing protocol.

EN343

Standardized European testing. Both waterproofing AND breathability certified.

Why Businesses Need EN343-Certified Rainwear

Compliance With European PPE Regulations

For companies operating in Europe or serving European markets, EN343 certification isn’t optional – it’s a legal requirement for personal protective equipment. The PPE Regulation (EU) 2016/425 mandates that protective clothing meets specific performance standards, and EN343 provides the framework for weather protection.

⚠️ Regulatory Requirements

- Mandatory for PPE suppliers in EU market

- Required for government and public sector procurement

- Essential for ISO 9001 certified organizations

- Critical for insurance and liability protection

Worker Safety in Harsh Weather

Non-certified rainwear creates genuine safety risks for outdoor workers. Inadequate waterproofing leads to wet clothing, while poor breathability causes overheating and heat stress – both serious workplace hazards.

Liability Protection for Employers

Using certified EN343 rainwear demonstrates due diligence in worker protection. In case of weather-related incidents, certified equipment provides legal protection and reduces liability exposure.

Why Buyers Prefer Certified Gear

Professional buyers consistently choose EN343-certified products because they offer:

- Predictable Performance: Certified products perform consistently across batches

- Reduced Risk: Lower failure rates and warranty claims

- Procurement Efficiency: Standardized specifications simplify purchasing

- Brand Protection: Quality standards protect brand reputation

Types of EN343 Raincoats

Industrial Workwear Raincoats

Heavy-duty rainwear designed for manufacturing, construction, and industrial applications. These garments prioritize durability and protection over lightweight comfort.

High-Visibility EN343 + EN ISO 20471 Combinations

Integrated safety solutions that combine weather protection with high-visibility requirements for roadside work, construction sites, and emergency services.

Construction & Building

Class 2-3 ratings, reinforced seams, multiple pockets

Transportation & Logistics

Hi-vis integration, reflective strips, mobility features

Utilities & Infrastructure

Utility pockets, tool loops, extended coverage

Lightweight Breathable Jackets

Premium rainwear for professional users who need protection without bulk. Advanced membrane technology provides excellent breathability while maintaining waterproof integrity.

Heavy-Duty PVC / PU / Oxford Options

Traditional materials updated with modern construction techniques. These proven fabrics offer excellent value for applications where extreme durability is prioritized over comfort.

Sustainable & Eco-Friendly Raincoat Options

Growing market demand for environmentally responsible workwear has driven innovation in sustainable materials and manufacturing processes.

How to Choose a Reliable EN343 Supplier

What Certifications They Must Provide

Legitimate EN343 suppliers should readily provide:

EN343 Test Reports

Third-party laboratory testing results showing waterproof and breathability performance

CE Marking Documentation

EU conformity declaration and CE marking evidence

PPE Regulation Compliance

Documentation showing compliance with EU Regulation 2016/425

Factory Audit Checklist

For serious B2B buyers, conducting factory audits ensures quality and compliance:

| Audit Area | Key Requirements | Documentation Required |

|---|---|---|

| Quality Management | ISO 9001 certified facility | ISO certificate, audit reports |

| Testing Capabilities | In-house or partner lab testing | Test equipment calibration records |

| Material Sourcing | Certified material suppliers | Material certificates, test reports |

| Production Control | Documented production processes | SOPs, quality control procedures |

Quality Testing Methods to Ask For

Reputable suppliers should offer transparent testing processes:

Water Resistance Testing

AATCC 35 or ISO 811 hydrostatic head testing

Breathability Testing

ASTM E96 or ISO 15496 moisture vapor transmission testing

Seam Integrity Testing

ISO 5081 seam strength and water penetration testing

Red Flags When Choosing a Supplier

Be wary of suppliers who:

- Cannot provide current EN343 certificates

- Offer prices significantly below market rates

- Refuse factory visits or third-party audits

- Have limited production capacity or quality control systems

- Cannot provide references from similar-sized companies

Materials Used in EN343 Raincoats

PU-Coated Polyester

The most common base material for EN343 rainwear. PU (polyurethane) coating provides excellent waterproofing while maintaining flexibility and durability.

Performance Characteristics

- Waterproofing: 2,000-10,000 mm hydrostatic head

- Breathability: 3,000-8,000 g/m²/24h MVTR

- Durability: Excellent tear and abrasion resistance

- Cost: Moderate, excellent value proposition

PVC Rainwear

Heavy-duty material for extreme conditions. PVC (polyvinyl chloride) offers superior waterproofing but reduced breathability compared to PU-coated fabrics.

Oxford Fabric & Ripstop

Woven base fabrics that provide excellent tear resistance. Often used as outer layers in multi-layer EN343 constructions.

TPU / ECO Alternatives

Thermoplastic polyurethane and eco-friendly alternatives are gaining market share as sustainability becomes a priority in PPE procurement.

Breathable Membrane Technology

Advanced materials like Gore-Tex, SympaTex, and proprietary membranes that provide superior breathability while maintaining waterproof integrity.

The EN343 Manufacturing Process

Seam Sealing Techniques

Proper seam sealing is critical to EN343 performance. Modern manufacturing uses multiple techniques to ensure waterproof seams:

Step 1: Seam Preparation

Precision cutting and edge preparation to ensure clean seams

Step 2: Tape Application

Heat-activated waterproof tape applied to seam joints

Step 3: Heat Activation

Thermal bonding process to create permanent waterproof seal

Step 4: Quality Inspection

Visual and pressure testing to verify seam integrity

Waterproof Coating Application

Advanced coating processes ensure consistent waterproofing performance across the entire garment surface.

Breathability Testing

Final breathability testing ensures the coating process hasn’t compromised moisture vapor transmission.

Final Quality Inspection

Comprehensive quality control including visual inspection, performance testing, and certification verification.

Certifications & Compliance Requirements

Documentation Buyers Should Request

Professional procurement requires comprehensive documentation:

Test Reports

Independent laboratory verification of EN343 performance

Certificates of Conformity

Manufacturer declarations of compliance with standards

Material Certificates

Documentation of base fabric and coating materials

REACH Compliance for Europe

European REACH regulation compliance is mandatory for all materials used in EN343 rainwear sold in Europe.

PPE Regulation (EU) 2016/425

Complete compliance with European PPE regulation requirements, including risk assessment and user information.

Co-Certifications: EN ISO 20471, EN14058, EN510, etc.

Many EN343 rainwear products include additional certifications for specific applications:

EN ISO 20471

High-visibility clothing requirements

EN14058

Protection against cold environments

EN510

Protection against entanglement with moving parts

Customization Options

Logo Printing & Branding

Professional embroidery, printing, and appliqué options for brand identity integration.

Color Options for Workwear

Standard industrial colors plus custom color matching for brand consistency.

Reflective Strips and High-Visibility Elements

EN ISO 20471 compliant reflective materials integrated into EN343 construction.

Custom Design Engineering for Brands

Complete custom garment development from pattern design to final certification.

Industries That Need EN343 Raincoats

Construction

Outdoor construction work requires durable, Class 2-3 EN343 rainwear with reinforced construction and practical pocket placement.

Transportation & Logistics

Loading bay operations and roadside maintenance demand hi-vis EN343 rainwear with EN ISO 20471 certification.

Utilities (Gas, Electricity, Water)

Utility workers need specialized EN343 rainwear with utility pockets, tool loops, and extended coverage designs.

Agriculture & Outdoor Workers

Farming and agricultural operations require cost-effective EN343 rainwear suitable for extended outdoor exposure.

Government Procurement

Public sector procurement typically requires EN343 certification for weather protection equipment.

Working With Overseas EN343 Suppliers

Asia vs. Europe Manufacturers

Asian manufacturers often offer cost advantages, while European manufacturers provide closer proximity and regulatory familiarity.

Asian Suppliers

- Lower manufacturing costs

- Larger production capacity

- Extended shipping times

- Regulatory compliance complexity

European Suppliers

- Regulatory expertise

- Shorter shipping times

- Higher production costs

- Quality assurance proximity

MOQ Requirements

Minimum order quantities typically range from 500-5,000 pieces depending on customization complexity.

Lead Times & Production Capacity

Standard lead times: 45-90 days for custom EN343 rainwear, depending on complexity and quantity.

DDP Shipping to Europe

Delivered Duty Paid shipping ensures predictable total landed costs for European buyers.

Price Breakdown

Material Costs

Base materials typically represent 40-60% of total manufacturing cost. Premium membranes and coatings significantly impact pricing.

Customization Costs

Logo printing, color matching, and design modifications add 10-30% to base pricing.

Certification Costs

EN343 testing and certification typically adds $5-15 per garment depending on testing scope.

Shipping Costs

International shipping and import duties can add 15-25% to total costs for overseas suppliers.

| Cost Component | Percentage | Typical Range |

|---|---|---|

| Base Materials | 40-60% | $8-25 per piece |

| Manufacturing Labor | 15-25% | $3-8 per piece |

| Customization | 10-30% | $2-10 per piece |

| Certification | 5-10% | $1-3 per piece |

| Shipping & Duties | 15-25% | $3-8 per piece |

Common Mistakes Buyers Make

Ignoring Breathability Ratings

Focusing only on waterproofing leads to uncomfortable, moisture-trapping garments that compromise worker productivity and safety.

Choosing the Wrong Material for the Job

Selecting lightweight materials for heavy-duty applications or vice versa results in premature failure or unnecessary expense.

Not Requesting Certification Reports

Accepting supplier claims without independent verification risks receiving non-compliant products.

Overlooking Seam-Sealing Quality

Poor seam sealing is the primary cause of EN343 failures, yet it’s often overlooked in supplier evaluation.

Future Trends in EN343 Rainwear

Sustainability

Growing demand for recycled materials and sustainable manufacturing processes is driving innovation in eco-friendly EN343 rainwear.

Lighter, More Breathable Fabrics

Advanced membrane technology is enabling lighter-weight rainwear with superior breathability ratings.

Smart Wearables

Integration of sensors and connectivity features for safety monitoring and performance tracking.

Modular Rain Gear

Modular designs that allow users to customize protection levels based on changing conditions.

Conclusion + 5 Useful FAQs

EN343 certification represents the gold standard for professional waterproof workwear. Choosing the right supplier requires understanding both the technical requirements and the business implications of certified PPE procurement.

Frequently Asked Questions

What is the minimum order quantity (MOQ) for EN343 rainwear?

MOQs typically range from 500-5,000 pieces depending on customization requirements and supplier capacity. Some suppliers offer smaller quantities for standard designs.

How long does EN343 certification last?

EN343 certification doesn’t expire, but manufacturers must retest when materials or construction methods change significantly. Most buyers require annual certification updates.

Can I get EN343 rainwear in custom colors?

Yes, most suppliers offer custom color matching. However, custom colors may affect MOQs and lead times. Standard industrial colors typically have better availability and pricing.

What testing is required for EN343 compliance?

EN343 requires waterproof resistance testing (ISO 811) and breathability testing (ISO 15496). Tests must be conducted by accredited laboratories.

How do I verify supplier EN343 claims?

Request current test reports from accredited laboratories, verify CE marking documentation, and consider third-party factory audits for serious procurement.

Ready to Source EN343 Rainwear?

Get competitive quotes from pre-vetted EN343 suppliers with proven track records.