Your Premier Manufacturer for Custom Bulk Plus Size Raincoats & Waterproof Apparel

Unmatched Material Expertise for Every Performance & Budget Requirement

As a specialist manufacturer, our value proposition begins with a profound understanding of technical textiles. Your product’s performance, cost, and market positioning are fundamentally determined by the material choices made at the outset. We guide our B2B partners through the complex landscape of waterproof fabrics, ensuring every bulk order is built on a foundation of optimal material selection. Our direct relationships with top-tier mills allow us to source a comprehensive range of textiles, from high-performance synthetics to cost-efficient polymers, each with verifiable technical specifications. We engage with your procurement and design teams to analyze your end-use case, target cost-per-unit, and desired performance metrics—such as hydrostatic head ratings, moisture vapor transmission rates (MVTR), and durability requirements. This consultative approach de-risks your investment, guaranteeing the final product aligns perfectly with your brand promise and commercial objectives, whether you are developing premium outdoor gear, high-volume promotional items, or durable workwear. Our expertise is not just in sourcing, but in understanding how each material behaves during cutting, sewing, and seam sealing, ensuring manufacturability and consistent quality at scale.

High-Performance Polyester & Nylon Raincoats

For applications demanding a superior balance of durability, low weight, and technical performance, Polyester and Nylon are the industry standards. We offer a comprehensive portfolio of these woven fabrics, tailored for sophisticated OEM and ODM projects. Our Polyester range, typically from 75D to 300D, is renowned for its excellent UV resistance, dimensional stability, and robust colorfastness, making it ideal for corporate branding and workwear. We offer it with various coatings, including Polyurethane (PU) and advanced DWR (Durable Water Repellent) finishes, achieving waterproof ratings from 2,000mm to over 10,000mm.

Our Nylon selection, including high-tenacity ripstop variants, provides an exceptional strength-to-weight ratio, perfect for performance-oriented rain jackets where packability and tear resistance are critical. We can source Nylon fabrics with breathable membranes laminated to the inner face, delivering high MVTR values (e.g., 5,000 to 15,000 g/m²/24h) for active-use comfort. Every fabric lot is accompanied by a technical data sheet specifying its weight (GSM), thread count, coating type, and certified performance ratings, ensuring complete transparency and adherence to your tech pack. We collaborate with your technical designers to select the precise textile that meets the functional and aesthetic requirements of your brand.

Cost-Effective & Durable PVC & TPU Solutions

When absolute water impermeability and cost-efficiency are the primary drivers, our polymer film solutions deliver uncompromising performance. Polyvinyl Chloride (PVC) is the definitive choice for heavy-duty industrial applications, emergency services apparel, and high-volume promotional rainwear where durability and budget are paramount. We manufacture PVC raincoats in various thicknesses, typically from 0.10mm to 0.35mm, with high-frequency welded seams that create a completely waterproof barrier, far exceeding the protection of a sewn garment. This makes it ideal for commercial fishing, construction, and event security.

For clients seeking a more advanced, flexible, and environmentally conscious alternative to PVC, we propose Thermoplastic Polyurethane (TPU). TPU is a superior polymer that offers the waterproof benefits of PVC but with enhanced elasticity, better abrasion resistance, and superior low-temperature flexibility. Crucially, TPU is phthalate-free and can be more easily recycled. It serves as an excellent material for mid-range consumer products and premium promotional items where a softer hand-feel and a better environmental profile are desired. We can apply TPU as a standalone film or as a coating on polyester fabric, providing a versatile solution that bridges the gap between basic PVC and high-end technical textiles. We guide our clients on the technical trade-offs between cost, durability, and features to align the material with their specific market segment.

Eco-Friendly EVA & PEVA Rain Ponchos

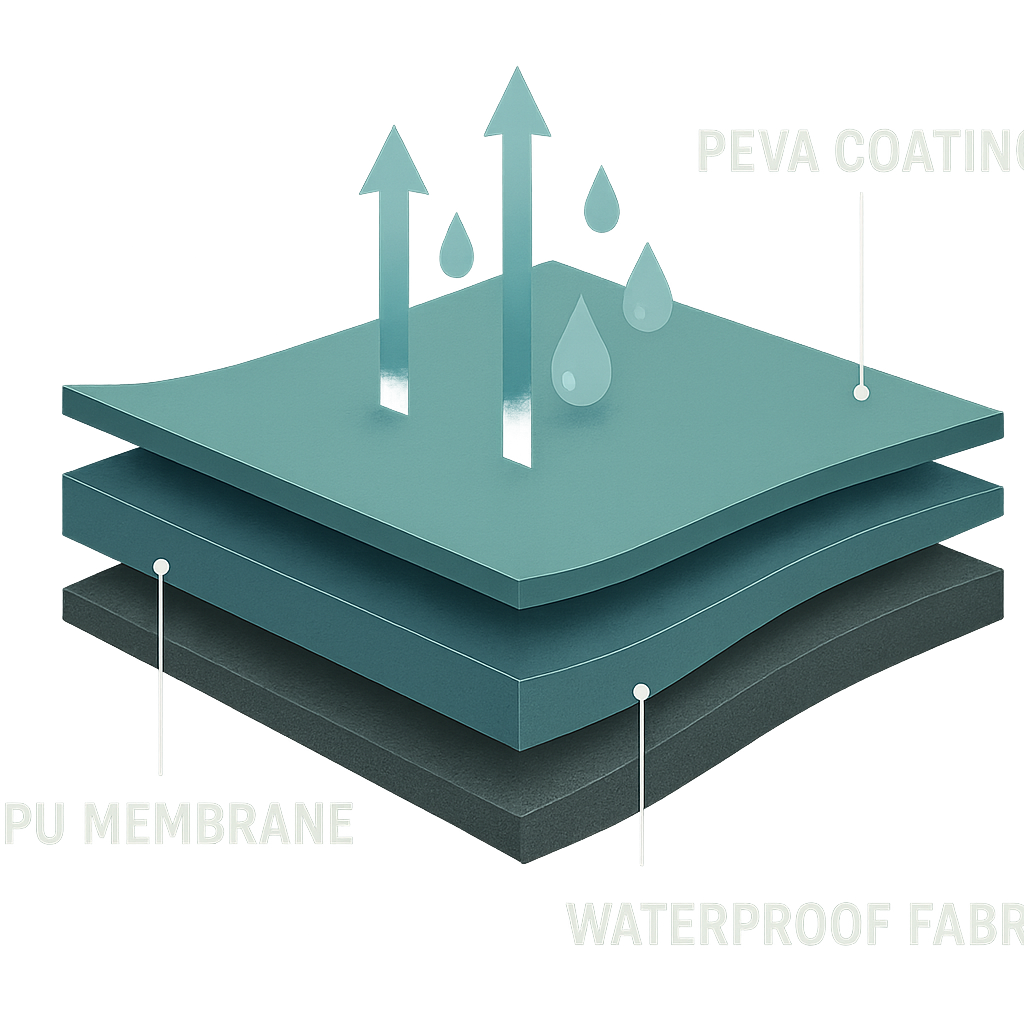

Addressing the growing market demand for sustainable and non-toxic material options, we specialize in the large-scale production of rainwear using EVA (Ethylene Vinyl Acetate) and PEVA (Polyethylene Vinyl Acetate). These materials are the premier choice for B2B clients in the events, tourism, and promotional products industries who require lightweight, portable, and eco-friendlier alternatives to traditional PVC. As chlorine-free and phthalate-free polymers, both EVA and PEVA avoid the environmental and health concerns associated with PVC, a critical consideration for brands targeting families, schools, and eco-conscious consumers.

EVA is prized for its softness, flexibility, and rubber-like feel, making it suitable for higher-quality reusable ponchos found in theme parks and outdoor venues. It offers superior durability for multi-use applications. PEVA, a copolymer of polyethylene and EVA, provides a highly cost-effective solution for disposable or limited-use ponchos, perfect for mass giveaways at sporting events, concerts, and festivals. We offer these materials in a range of thicknesses (typically 0.08mm to 0.15mm) and a wide spectrum of standard and custom Pantone-matched colors. The smooth surface is an excellent substrate for large-format screen printing, allowing for prominent brand and logo placement. By offering these PVC-alternatives, we enable our clients to meet their corporate social responsibility (CSR) goals and appeal to a broader, more environmentally aware customer base without compromising on function or budget.

Specialized Plus Size Design, Grading, and Manufacturing

Manufacturing for the plus-size market is a technical discipline that extends far beyond simply enlarging standard patterns. It requires a specialized approach to design, pattern making, and fit that acknowledges the unique anthropometric needs of the consumer. Our facility has invested heavily in the expertise and technology required to excel in this specific niche. We understand that a successful plus-size program hinges on achieving a comfortable, flattering, and consistent fit across the entire size range. This commitment addresses a critical pain point for brands and retailers: the high return rates and customer dissatisfaction that result from poorly executed plus-size grading. Our process is built on a foundation of data-driven pattern blocks, advanced digital tools, and a rigorous, multi-stage sampling process. We work as a technical partner to our clients, translating their brand’s fit identity into a commercially successful plus-size line. This specialized focus ensures that your final products not only meet your technical specifications but also resonate deeply with your target end-consumer, fostering brand loyalty and market leadership.

Advanced Pattern Grading for Consistent Fit

Effective plus-size grading is a complex science that is fundamental to our manufacturing process. We reject the simplistic "linear scaling" approach, which often leads to poor fit in larger sizes, such as disproportionately long sleeves, overly wide shoulders, or constricted hip measurements. Instead, our technical team employs advanced non-linear grading rules within our Gerber CAD systems. These rules are based on extensive data and experience with plus-size body shapes, ensuring that key areas like the armscye, bust-to-waist ratio, and hip-to-thigh circumference are adjusted proportionately.

Our process ensures that as the size increases, the garment’s shape evolves to provide adequate room and comfort where it is most needed, while maintaining the original design’s aesthetic integrity. We meticulously manage grade rule application to maintain balance points and ensure the garment hangs correctly on the body across all sizes. This technical rigor prevents the common pitfalls of plus-size manufacturing and guarantees a consistent, reliable fit from an XL to a 6XL. By providing this level of precision, we empower our clients to build a reputation for quality and fit within the lucrative and often underserved plus-size market.

Inclusive Sizing from XL to 6XL+

Our production capabilities are engineered to fully support inclusive sizing strategies. We offer a standard manufacturing range that extends from XL up to 6XL, with the technical capacity to develop patterns and produce garments beyond this range based on specific client requirements. Our expertise is not merely in producing these sizes, but in understanding the specific pattern adjustments they require. We have developed proprietary base patterns (or "blocks") for plus sizes that serve as a technically sound starting point for any new custom design. This pre-existing foundation accelerates the development process and reduces the risk associated with creating a new plus-size program from scratch.

We are fully equipped to work directly from your company’s established size charts and grading specifications to ensure seamless integration with your existing product lines. Alternatively, for clients new to the plus-size market, our technical team can provide consultation and propose a robust sizing schedule based on industry best practices and target demographic data. This flexibility allows us to serve as a strategic manufacturing partner for established plus-size brands and for companies looking to expand their market reach into this important consumer segment. Our commitment to inclusive sizing is a core component of our operational philosophy.

Prototyping and Fit Sample Approval Process

We operate on a principle of "no surprises." Our structured prototyping and fit sample approval process is designed to provide our clients with complete control and confidence before a single yard of bulk fabric is cut. This iterative, multi-stage process is critical for mitigating risk and ensuring the final product meets all technical and aesthetic requirements, especially in the nuanced domain of plus-size apparel.

- Initial Prototype (Proto Sample): Upon receipt of your technical pack or design concept, we create the first physical sample. This proto is used to evaluate the core design, construction techniques, and initial silhouette.

- Fit Sample: Based on feedback from the initial prototype, we produce a fit sample in a designated base size (e.g., 2XL). This sample is sent to you for live model fitting. We meticulously review your comments on all aspects of the fit—from shoulder slope and bust dart placement to sweep circumference and sleeve length.

- Revised Sample(s): We implement all requested changes and submit revised samples, continuing this collaborative feedback loop until the fit is perfected and formally approved.

- Pre-Production Sample (PPS): Once the fit is locked, we produce a final PPS. This sample is made using the actual bulk fabric and all final trims, zippers, and labels. It represents the "golden standard" for mass production. Your formal approval of the PPS is the final gate before we commence the full production run.

This transparent and rigorous approval process eliminates ambiguity, guarantees fidelity to your design vision, and ensures the commercial success of your plus-size program.

Full-Service OEM Program: Your Brand, Our Production Power

Our Original Equipment Manufacturer (OEM) program is the cornerstone of our B2B partnerships, designed for brands who have a complete vision and require a world-class production engine to bring it to life. We position ourselves as a seamless extension of your operations, transforming your detailed designs and technical specifications into finished, market-ready goods. This service is built on a foundation of precision, discretion, and unwavering adherence to your brand standards. You provide the blueprint—the technical package, the bill of materials, the brand guidelines—and we execute with meticulous attention to detail. Our OEM service allows you to leverage our extensive manufacturing infrastructure, our skilled workforce, and our established supply chain for raw materials and components, without the overhead of owning and operating your own factory. We handle the complexities of production management, from material sourcing to quality control, allowing you to focus your resources on design innovation, marketing, and distribution. Our commitment is to protect your intellectual property and deliver a product that is indistinguishable from one produced in your own facility, ensuring consistency and quality for your customers.

Private Label & Logo Integration (Screen Print, Heat Transfer)

The visual representation of your brand on the final product is paramount. We offer a comprehensive suite of logo integration and private labeling services to ensure your branding is executed with precision and durability. Our capabilities are engineered to match your exact brand guidelines and technical requirements.

- Screen Printing: Ideal for large, solid-color graphics and logos, screen printing offers excellent durability and a cost-effective solution for high-volume orders. We use high-quality, pliable inks formulated specifically for waterproof fabrics like PVC, Polyester, and Nylon to prevent cracking and peeling. We can execute multi-color designs with precise registration and can Pantone-match colors to ensure brand consistency.

- Heat Transfer: For complex, multi-color, or photorealistic logos, heat transfer is the superior method. This process allows for intricate detail and vibrant color gradients that are difficult to achieve with screen printing. We use industrial-grade transfer materials and application processes to ensure the logo bonds permanently with the fabric, withstanding wear and washing.

Beyond external logos, we manage all aspects of private labeling, including the sourcing and application of custom-woven neck labels, printed care instructions, and branded hang tags, ensuring every element of the product aligns with your brand identity.

Custom Hardware, Zippers, and Trim Sourcing

The perceived quality of a garment is often judged by its components. We recognize that hardware and trims are not afterthoughts but critical elements of the overall design and function. As part of our comprehensive OEM service, we manage the sourcing of all custom components to match your exact specifications. Our established and pre-vetted network of hardware and trim suppliers allows us to procure a vast array of items, mitigating supply chain risks for your brand.

Our sourcing capabilities include:

- Zippers: Sourcing from reputable suppliers like YKK or providing high-quality generic equivalents, including waterproof zippers, reverse-coil zippers, and custom-molded zipper pulls featuring your logo.

- Snaps, Grommets & Rivets: Custom-finished metal or plastic snaps (e.g., matte black, antique brass), branded grommets, and reinforcing rivets that align with your aesthetic.

- Cord Locks, Toggles & Aglets: A full range of plastic and metal cord management hardware for hoods and hems, including the option for custom-molded or branded pieces.

- Seam Sealing Tape: Sourcing the appropriate tape with the correct thickness and adhesive properties to guarantee the waterproof integrity of seams on different base fabrics.

By managing this complex sourcing process, we ensure that every single component, no matter how small, adheres to your Bill of Materials (BOM) and quality standards.

Adherence to Your Exact Technical Specifications

The technical package (or "tech pack") is the single source of truth in our OEM process. We operate with the understanding that our primary responsibility is to execute every detail within your tech pack with absolute fidelity. Our production managers, pattern makers, and quality control teams are trained to treat the tech pack as a binding contract, ensuring that your design intent is perfectly translated into the final product.

Our adherence process covers all critical technical checkpoints:

- Bill of Materials (BOM): We verify and source every fabric, thread, trim, and label according to your specified suppliers, part numbers, and color codes.

- Construction Details: We follow your exact instructions for seam construction, stitch types, and stitch-per-inch (SPI) requirements. For waterproof garments, this includes precise application of seam sealing tape to all specified seams.

- Measurement Tolerances: We build to your graded measurement chart, implementing rigorous in-line and final quality control checks to ensure all points of measure (POM) are within your specified tolerance (e.g., +/- 1cm).

- Finishing & Packaging: We follow all instructions for pressing, folding, bagging, and carton labeling to ensure the products arrive at your distribution center in the specified, retail-ready condition.

This disciplined, process-driven approach guarantees consistency across your entire bulk order and gives your technical design team complete confidence in our ability to deliver on your brand’s promise of quality.

Collaborative ODM Solutions: From Concept to Container

Our Original Design Manufacturer (ODM) program is a strategic partnership designed for businesses seeking to launch new waterproof apparel lines but who may not have in-house design or product development resources. This service transforms our factory from a simple production unit into your comprehensive product development partner. We take your initial idea—whether it’s a simple sketch, a set of functional requirements, or a target market opportunity—and manage the entire journey from concept to container. Our experienced team of designers, material experts, and merchandisers works collaboratively with you to develop a unique product that is tailored to your brand and commercially viable. The ODM model is an ideal solution for promotional product companies, new private label brands, or established retailers looking to expand their offerings without the significant investment required to build a full-scale design department. We provide the market intelligence, design creativity, and technical expertise, allowing you to focus on your core strengths in sales and marketing. This turnkey solution accelerates your time-to-market and leverages our industry experience to create innovative and profitable products.

Initial Design Consultation & Trend Analysis

The ODM process begins with a deep-dive consultation to understand your vision and commercial goals. This is more than just a requirements-gathering session; it is a strategic workshop where we align on the project’s core objectives. We work with you to define the target consumer, the desired market positioning (e.g., value, mid-tier, or premium), key functional features, and target cost-of-goods.

Leveraging our position in the industry, we provide valuable market and trend analysis. Our team constantly monitors the global apparel landscape, identifying emerging trends in silhouettes, color palettes, material innovations, and functional features specific to the rainwear and outdoor apparel sectors. We can present you with mood boards, trend reports, and competitive analysis to help shape the design direction. This initial phase ensures the product we develop is not created in a vacuum but is informed by current market data, giving it the best possible chance for commercial success. We distill this collaborative brainstorming into a concrete product brief that will guide the entire development process.

Material Sourcing and Performance Matching

A key value proposition of our ODM service is our ability to translate your desired product performance into tangible material specifications. You define the "what," and we determine the "how." For instance, you might specify a need for a "lightweight, packable jacket for urban commuters that can withstand a 30-minute downpour and has a retail price under $50." Our technical team will take these functional and commercial parameters and engineer the optimal product solution.

We will propose a curated selection of materials for your consideration, explaining the technical trade-offs of each. This could involve recommending a 190T Polyester with a 3,000mm PU coating for balanced performance and cost, or suggesting a lightweight 75D ripstop nylon for enhanced packability. We will propose specific seam construction methods (e.g., fully seam-sealed vs. critically seam-sealed) to align with the waterproof requirements and budget. This performance matching service de-risks the development process, leveraging our deep material science expertise to ensure the final product delivers on its promise to the end consumer. We handle the complexity of sourcing and testing, presenting you with clear options that meet your performance, aesthetic, and cost targets.

Complete Product Development & Lifecycle Management

Our ODM program offers a true end-to-end solution, managing every stage of the product’s creation from a nascent idea to a fully realized, shipping product. This comprehensive lifecycle management allows you to operate with a lean team while accessing a full suite of professional product development services.

The lifecycle we manage includes:

- Concept & Design: Developing initial sketches and technical drawings based on our consultation.

- Material & Trim Sourcing: Procuring all necessary fabrics and components.

- Pattern Making & Prototyping: Creating the initial patterns and building the first samples for fit and construction review.

- Iterative Sampling: Refining the product over multiple sample stages based on your feedback until a "golden sample" is approved.

- Costing & MOQ Finalization: Providing transparent, detailed costing at each stage to ensure the project remains on budget.

- Mass Production: Overseeing the entire production run, including cutting, sewing, and assembly.

- Quality Assurance: Implementing our rigorous QC protocols throughout the production process.

- Packaging & Logistics: Managing the final packaging, labeling, and coordination of shipment.

This turnkey service provides a streamlined, efficient, and reliable path to market for your private label rainwear program. We handle the operational complexity, you approve the key milestones, and together we build a successful product line.

Our Ironclad Commitment to Quality Assurance & Control

In the B2B manufacturing sector, consistent quality is the currency of trust and the foundation of long-term partnerships. We recognize that for our clients, product quality is non-negotiable; it is a direct reflection of your brand’s integrity and a key driver of customer loyalty. Therefore, our commitment to Quality Assurance (QA) and Quality Control (QC) is not a final step in our process, but a philosophy embedded in every stage of production. We have implemented a multi-layered quality management system designed to be proactive, not reactive—identifying and correcting potential issues at their source rather than merely catching defects at the end of the line. This system is built on internationally recognized standards, rigorous inspection protocols, and a culture of accountability. Our investment in robust QA/QC processes provides our clients with peace of mind, reduces the risk of costly defects and returns, and ensures that every unit shipped from our facility meets or exceeds the specifications outlined in your technical package.

In-Line Production Inspections & AQL Standards

We believe that quality must be built into the product, not inspected into it. To achieve this, we employ a system of rigorous in-line production inspections at critical control points throughout the manufacturing process. Our dedicated QC staff are present on the factory floor, monitoring and validating quality in real-time.

Key in-line inspection points include:

- Fabric & Raw Material Inspection: All incoming materials are inspected for defects, color consistency, and conformity to technical specifications before they are accepted into inventory.

- Cutting Inspection: We verify the accuracy of cut panels against the approved patterns to ensure dimensional precision from the very first step.

- Sewing Line Audits: QC inspectors patrol the sewing lines, performing random checks on semi-finished goods to verify stitch quality, seam integrity, and correct construction methods.

- Post-Assembly Check: Before final finishing, every garment is checked for major construction flaws or cosmetic defects.

All inspections are governed by the Acceptable Quality Limit (AQL) standard, typically AQL 2.5 for major defects and AQL 4.0 for minor defects, or as specified by the client. This statistical, standardized approach ensures an objective and consistent measure of quality across all production runs.

Third-Party Testing & Certification (Waterproof, Seam Sealing)

To provide our clients with objective, verifiable proof of product performance, we fully support and facilitate third-party testing and certification. While our in-house labs conduct routine testing, we understand the value and authority that independent verification provides, especially for technical performance claims. We maintain strong working relationships with internationally recognized testing laboratories such as SGS, Intertek, TUV, and Bureau Veritas.

We can coordinate a comprehensive testing program based on your requirements, which can include:

- Hydrostatic Head Test (e.g., ISO 811, AATCC 127): To certify the waterproof rating (mm) of the fabric and seams.

- Moisture Vapor Transmission Rate (MVTR) Test: To validate the breathability rating (g/m²/24h) of performance fabrics.

- Seam Tape Adhesion Test: To ensure the durability of the seam sealing after washing and flexing.

- Chemical & Substance Testing: Verifying compliance with regulations like REACH or CPSIA, ensuring the absence of restricted substances like phthalates or heavy metals.

We manage the entire process of submitting samples and provide you with the official laboratory reports and certificates, offering transparent and undeniable evidence of your product’s quality and safety compliance.

Final Pre-Shipment Quality Audits

The final pre-shipment inspection is the ultimate gatekeeper, representing our last opportunity to confirm that an order is 100% compliant with our client’s standards before it leaves our control. This comprehensive audit is conducted by a separate final inspection team, who act as a proxy for the client. The process is performed after the entire order has been produced and at least 80% of the goods are fully packed for export.

Following a sampling plan based on AQL standards, our inspectors randomly select finished, packed cartons and conduct a thorough examination covering:

- Workmanship & Aesthetics: Checking for any sewing defects, uncut threads, stains, or cosmetic issues.

- Measurement Conformity: Measuring garments against the approved graded specifications to ensure they are within tolerance.

- Labeling & Packaging: Verifying that all labels (neck, care, hang tags) are correct and that the product is folded, bagged, and packed according to the client’s instructions.

- Quantity & Assortment Verification: Confirming that the carton counts and the size/color assortment within the cartons are correct.

A detailed inspection report, complete with photographs, is generated and can be provided to the client for review before the shipment is authorized for release. This final, rigorous check guarantees that what you receive is precisely what you ordered.

Resilient Supply Chain & Global Logistics Management

In today’s volatile global market, a resilient and transparent supply chain is as critical to your business success as the quality of the product itself. We have architected our supply chain and logistics operations to be a source of competitive advantage for our clients, emphasizing reliability, flexibility, and clear communication. Our approach goes beyond simple order fulfillment; we engage in proactive supply chain management to mitigate risks, optimize lead times, and provide you with the logistical control necessary to manage your inventory and meet your market deadlines. From the strategic sourcing of raw materials to the final delivery of goods to your port or warehouse, our experienced logistics team manages the intricate details of the global supply chain. This allows you to focus on your business, confident that a professional team is navigating the complexities of production scheduling, customs clearance, and international freight on your behalf. Our goal is to make the entire procurement process as seamless and predictable as possible, transforming potential logistical hurdles into a smooth and efficient flow of goods.

Transparent Lead Time & Production Scheduling

Uncertainty in production timelines is a major pain point for procurement managers. We address this directly by providing clear, transparent, and realistic production schedules for every order. Upon order confirmation and receipt of your deposit, our planning department issues a detailed Critical Path Analysis (CPA). This master schedule outlines all key milestones and their corresponding deadlines, providing you with a complete roadmap for your production run.

The typical CPA includes dates for:

- Raw Material Sourcing & Delivery

- Lab Dip & Strike-Off Approvals

- Pre-Production Sample (PPS) Approval

- Commencement of Cutting & Mass Production

- In-line Quality Control Checkpoints

- Final Quality Audit Window

- Ex-Factory Date (Goods ready for shipment)

- Vessel Booking & Departure Date

Our project management team provides regular updates and proactively communicates any potential deviations from the schedule, allowing you to adjust your own planning accordingly. This commitment to transparency fosters a collaborative partnership and eliminates the costly surprises that can arise from poor production visibility.

Strategic Raw Material Sourcing & Inventory

The foundation of a reliable production schedule is the timely availability of quality raw materials. We have cultivated long-standing, high-volume relationships with a strategic portfolio of pre-vetted fabric mills and trim suppliers. This not only ensures access to high-quality materials but also gives us priority status and negotiating leverage, which we pass on to our clients. Our sourcing strategy is built on diversification, maintaining relationships with multiple suppliers for critical materials to mitigate risks associated with single-source dependency.

For clients with ongoing, high-volume programs, we can implement more advanced inventory management strategies. This may include pre-booking greige goods (undyed fabric) or maintaining a safety stock of your specific branded materials in our warehouse. These strategic inventory programs can significantly shorten production lead times for repeat orders, buffer against raw material price volatility, and provide a greater degree of agility in responding to fluctuations in market demand. This proactive approach to material management is a key component of our supply chain resilience.

FOB, CIF, and DDP Shipping Term Capabilities

We understand that our global clients have diverse logistical needs and varying levels of in-house expertise. To accommodate this, we offer a full spectrum of Incoterms (International Commercial Terms), providing the flexibility to choose a shipping arrangement that best suits your business model. Our experienced logistics department can manage and quote for a variety of options:

- FOB (Free On Board): This is a common arrangement where we are responsible for all costs and processes up to and including loading the goods onto the vessel at the designated port of departure (e.g., FOB Shanghai). From that point, you or your designated freight forwarder take control of the ocean freight, insurance, and destination charges.

- CIF (Cost, Insurance, and Freight): Under this term, we manage and pay for the cost of the goods, the insurance, and the ocean freight to your designated port of destination. You are responsible for customs clearance and inland transportation in your country.

- DDP (Delivered Duty Paid): This is our most comprehensive, turnkey logistics solution. We manage the entire shipping process from our factory door to your final warehouse or distribution center. This includes ocean freight, insurance, customs clearance, import duties, and final inland delivery. DDP simplifies your procurement process immensely, providing you with a single, all-inclusive cost and eliminating the complexities of managing international logistics.

Tailored Rainwear Solutions for Diverse B2B Markets

We understand that a "one-size-fits-all" approach to manufacturing is ineffective. Different markets have vastly different requirements for performance, aesthetics, cost, and compliance. Our production philosophy is built on market-specific specialization, allowing us to act as an expert partner for a diverse range of B2B clients. We have configured our design, sourcing, and production lines to meet the unique demands of the outdoor, corporate, and fashion retail sectors. This specialized knowledge enables us to provide targeted recommendations, anticipate market-specific challenges, and engineer products that are not just well-made, but perfectly suited for their intended end-use and commercial environment. Whether your priority is extreme technical performance, precise brand representation, or on-trend design, we have the experience and infrastructure to deliver. Our goal is to translate your market-specific objectives into a tangible product that creates a competitive advantage for your brand.

Outdoor & Sporting Goods Brands

For brands in the outdoor and sporting goods sector, performance is not a feature—it is the core of the product’s value proposition. We speak the language of technical apparel and understand that your customers demand products that can withstand the rigors of the elements. Our manufacturing process is geared towards meeting and exceeding the high standards of this market. We collaborate with your technical designers to build rainwear that delivers on key performance indicators (KPIs) such as high hydrostatic head ratings (waterproofness, often targeting 10,000mm to 20,000mm) and excellent Moisture Vapor Transmission Rates (MVTR for breathability, e.g., 10,000g/m²/24h or higher).

Our expertise covers the critical details: specifying 2.5-layer or 3-layer laminated fabrics, ensuring full seam taping with appropriate high-density tape, and sourcing premium components like YKK® AquaGuard® water-resistant zippers and Cohaesive™ cord management systems. We work with plus-size patterns that account for athletic builds and layering, ensuring freedom of movement. We also facilitate rigorous third-party testing to validate these performance claims, providing the data and certifications you need to market your products with confidence. Our partnership provides you with a reliable manufacturing base to create technical, high-margin products that build brand loyalty among serious outdoor enthusiasts.

Corporate & Promotional Product Distributors

Clients in the corporate and promotional sectors require a unique blend of durability, brand fidelity, and cost-efficiency. The rainwear we produce for this market functions as a tangible representation of a brand’s identity, often used as employee uniforms, event staff apparel, or high-value corporate gifts. Our primary focus is on delivering impeccable brand consistency at scale. We excel at precise Pantone color matching for fabrics to align with corporate style guides. Our logo application capabilities, including high-durability screen printing and detailed heat transfers, ensure that your client’s branding remains crisp and intact through prolonged use.

We understand the importance of practicality and longevity in this segment. We typically recommend robust fabrics like 210T or 300D Polyester with a solid PU coating for a balance of excellent water resistance and the toughness required for daily wear. We also prioritize features like pack-away hoods, ample pocket space, and adjustable cuffs. For large-scale promotional events, we manufacture cost-effective PVC or PEVA ponchos with large, highly visible logo placements. We manage the entire process to deliver reliable, brand-accurate apparel that enhances your clients’ brand image and meets strict delivery deadlines for events and corporate rollouts.

Apparel Retail & Private Label Fashion

The fashion retail market moves at a rapid pace, driven by trends, fit, and perceived value. For our private label retail partners, we function as an agile and trend-aware manufacturing partner. Our service extends beyond mere production to include insights into current silhouettes, colors, and material textures. We understand that for plus-size fashion, fit and drape are paramount. Our advanced pattern grading ensures a flattering and comfortable fit that reduces return rates and builds customer trust.

We help you develop collections that are commercially viable, sourcing fabrics that offer the right hand-feel, finish (e.g., matte, cire, peach), and on-trend color palettes. We can create a diverse range of styles, from classic trench coats to modern, oversized parkas, incorporating fashion-forward details like custom-branded hardware, contrasting linings, and unique trim applications. We also understand the retail supply chain’s need for speed and can work towards compressed production timelines to help you capitalize on fast-moving trends. Our role is to provide the manufacturing backbone for your brand, delivering high-quality, fashion-conscious rainwear that enhances your brand’s aesthetic and profitability in the competitive retail landscape.

Navigating Sustainable & Eco-Conscious Manufacturing

In the modern marketplace, sustainability is no longer a niche interest but a core business imperative. B2B buyers and end-consumers alike are increasingly prioritizing brands that demonstrate a genuine commitment to environmental and social responsibility. We recognize our role in this ecosystem and have proactively integrated sustainable practices and materials into our core offerings. Our approach is to provide clients with a clear and viable pathway to developing more eco-conscious product lines without compromising on performance or commercial viability. We have invested in the knowledge and supply chain relationships necessary to navigate the complexities of sustainable sourcing, chemical compliance, and certification. By partnering with us, you can enhance your brand’s reputation, meet the growing demand for green products, and align your business with the principles of corporate social responsibility (CSR), turning sustainability into a powerful market differentiator.

Recycled Polyester & Nylon Fabric Options

One of the most impactful ways to reduce the environmental footprint of apparel is through the use of recycled materials. We offer a comprehensive range of high-quality fabrics made from recycled inputs, primarily rPET (recycled polyester) derived from post-consumer plastic bottles and recycled nylon from pre-consumer industrial waste. These textiles offer performance characteristics that are virtually indistinguishable from their virgin counterparts. Our recycled polyester and nylon fabrics can be treated with the same high-performance PU coatings and DWR finishes to achieve excellent waterproof and breathable ratings.

To ensure the integrity of these materials, we can source fabrics certified by the Global Recycled Standard (GRS). The GRS is a rigorous international standard that verifies the recycled content of fabrics and tracks the chain of custody from the recycler to the final product. It also sets strict social and environmental criteria for the manufacturing process. By choosing GRS-certified materials, you provide your customers with transparent, third-party validation of your product’s sustainability claims.

Phthalate-Free PVC and Biodegradable Additives

For applications where PVC is the preferred material due to its durability and cost-effectiveness, we offer safer, more environmentally aware alternatives. Our standard PVC offerings are formulated to be phthalate-free, specifically avoiding substances like DEHP and DBP, which have come under regulatory scrutiny and consumer concern. This ensures your products meet international safety standards like California Proposition 65 and REACH regulations in the EU.

Furthermore, we are innovating with materials that address end-of-life concerns. For PEVA and EVA ponchos, which are often used for short-term applications, we can source materials blended with biodegradable additives. These additives are designed to help the polymer break down more quickly in a landfill environment compared to conventional plastics. While not fully compostable, this represents a significant step forward in mitigating the long-term plastic waste associated with disposable rainwear, offering a compelling eco-story for event-based and promotional products.

Certifications (e.g., GRS, OEKO-TEX)

Third-party certifications are the gold standard for validating sustainability and safety claims in the textile industry. We actively work with suppliers and are prepared to manage production to meet the criteria of key international standards, providing our clients with the credibility needed in a discerning market.

- Global Recycled Standard (GRS): As mentioned, this is our primary certification for validating recycled content. We manage the chain of custody documentation required to ensure the final garment can be legitimately marketed as containing GRS-certified materials.

- OEKO-TEX® STANDARD 100: This is one of the world’s most recognized labels for textiles tested for harmful substances. We can ensure that all components of your product—from the fabric and thread to the zippers and buttons—are sourced from OEKO-TEX® certified suppliers. This certification provides a powerful assurance to consumers that the garment is safe for their skin and free from a long list of regulated and non-regulated substances that may be harmful to human health.

By building your products in adherence to these standards, we help you de-risk your supply chain, ensure regulatory compliance, and build a brand that is trusted for its commitment to safety and sustainability.

Custom Packaging, Labeling, and Go-to-Market Readiness

The journey of a product does not end when it leaves the sewing line. The final stages of packaging, labeling, and presentation are critical for ensuring logistical efficiency, retail appeal, and brand consistency. We provide a comprehensive suite of finishing services designed to transform your manufactured goods into go-to-market-ready products. Our team works closely with you to ensure that every aspect of the final presentation—from the custom hang tag to the carton shipping mark—aligns perfectly with your brand standards and the operational requirements of your distribution channels. This meticulous attention to detail protects the product in transit, optimizes it for your warehouse receiving process, and creates a positive first impression with the end consumer. We manage these final but crucial steps so your products arrive exactly as specified, ready for immediate sale or distribution.

Retail-Ready Branded Packaging Solutions

First impressions matter, especially in a competitive retail environment. We offer a range of custom packaging solutions to elevate your brand’s perceived value and protect the garment until it reaches the customer. We can source and produce various packaging options based on your specific needs and budget.

- Custom Polybags: We can source printed polybags featuring your logo, brand messaging, or recycling information. Options include standard LDPE bags, frosted CPE bags for a premium feel, or bags with resealable closures.

- Self-Fabric Pouches: For packable raincoats, we can design and manufacture a matching pouch made from the same shell fabric, often with a branded drawstring or zipper and a carabiner loop for convenience.

- Branded Boxes: For premium or gift-boxed items, we can coordinate the production of custom-printed retail boxes, ensuring the product is presented with maximum impact.

We ensure all packaging is applied carefully to prevent wrinkling and present the product in the best possible light, ready for the sales floor.

Custom Hang Tags, Care Labels, and Barcoding

Accurate and professional labeling is essential for brand identity, legal compliance, and inventory management. We manage the sourcing and application of all your custom trim components as specified in your technical package.

- Hang Tags: We can source or have you supply custom-designed hang tags, which we will apply to your exact specifications. This includes multi-part tag sets that communicate brand stories, technical features, and pricing information.

- Woven & Printed Labels: We will expertly sew in your custom-branded woven neck labels and apply legally required care and content labels (e.g., "Made in China," fiber content, washing instructions). We ensure placement is consistent across the entire production run.

- Barcoding & SKU Labeling: We understand the critical role of barcodes in modern logistics and retail. We can apply UCC/EAN barcode stickers to hang tags or polybags according to your specifications. This ensures your products are scannable upon arrival at your distribution center, streamlining your receiving and inventory management processes and preventing costly relabeling projects.

Bulk Packed vs. Individually Folded & Bagged Options

| Packing Method | Description | Best Suited For |

|---|---|---|

| Individually Folded & Bagged | Each garment is carefully folded to specified dimensions, placed in an individual polybag (often with a size sticker), and then packed into the master carton. This is the most common method for retail-ready goods. | Apparel retail brands, corporate gift programs, and any client requiring products to be immediately ready for sale or individual distribution. |

| Bulk Packed (Assorted Sizes) | Garments are folded and stacked directly into the master carton, often separated by size with a sheet of paper. Cartons are typically packed with a pre-defined size and color assortment (e.g., 1-S, 2-M, 2-L, 1-XL). This method is more space and cost-efficient. | Clients who will be re-processing or re-packaging goods at their own facility. It can reduce shipping volume and the cost of individual polybags. |

| Bulk Packed (Solid Size/Color) | Similar to above, but each master carton contains only one specific SKU (e.g., 24 pieces of Men’s Large in Navy). This method simplifies inventory management for clients with large-scale distribution centers that prefer to handle solid SKU cartons. | High-volume distributors, large retailers with automated warehousing, and uniform fulfillment programs. |

We will work with you to determine the most appropriate packing method and will ensure all master cartons are labeled with detailed shipping marks, including PO number, style number, size/color breakdown, carton dimensions, and weight, for easy identification.

Streamlined Procurement: Your Path to a Successful Bulk Order

Embarking on an overseas manufacturing project can seem daunting, which is why we have engineered a clear, transparent, and structured procurement process to guide our partners from initial inquiry to final delivery. Our system is designed to provide clarity, manage expectations, and ensure there are no surprises along the way. We believe that a successful partnership is built on communication and a well-defined workflow. This step-by-step process demystifies international sourcing, providing a predictable path for both seasoned procurement professionals and first-time buyers. Our dedicated project management team will lead you through each phase, ensuring that all your technical, commercial, and logistical requirements are met with precision. This structured approach mitigates risk, ensures quality, and builds the foundation for a long-term, successful manufacturing relationship.

Step 1: Initial RFQ and Technical Pack Submission

The process begins with your vision. To provide you with an accurate and timely quotation, we need to understand your product requirements in detail. The most effective way to communicate this is through a Request for Quotation (RFQ) accompanied by a technical package, or "tech pack."

- Request for Quotation (RFQ): Your RFQ should ideally include the target order quantity (per style/color), desired delivery date, and target price, which helps us to engineer the product to your commercial needs.

- Technical Package (Tech Pack): This is the blueprint for your product. A comprehensive tech pack is the single most important document for ensuring accuracy. It should include:

- Technical Sketches: Flat drawings of the front, back, and side of the garment.

- Bill of Materials (BOM): A list of all materials, including main fabric, lining, zippers, snaps, thread, and labels.

- Construction Details: Instructions on how the garment should be sewn (e.g., seam types, stitch density).

- Colorway Specifications: Pantone codes for all fabrics and trims.

- Artwork & Logo Details: Placement, size, and color information for all branding.

- Size Chart & Grading: A complete list of measurements for a base size and the grade rules for other sizes.

If you are at the concept stage (our ODM service) and do not have a full tech pack, a detailed description of the product, reference images, and functional requirements are a great starting point.

Step 2: Quotation, MOQ, and Sample Development

Once we receive your initial inquiry, our merchandising team will thoroughly review the information and begin the costing process.

- Quotation & MOQ: Within a few business days, we will return a detailed quotation. This will clearly state the unit price (e.g., FOB Shanghai), the Minimum Order Quantity (MOQ) required for that price, and the estimated production lead time. Our MOQs are determined by fabric minimums and production line efficiency, but we always strive to be as flexible as possible.

- Sample Development: Upon your approval of the quotation, we move to the sampling stage. This is a critical, iterative process to perfect the product before mass production. It typically involves:

- Proto Sample: The first physical sample to check the design and construction.

- Fit Sample: A sample in your base size for you to conduct a live model fitting and provide feedback.

- Pre-Production Sample (PPS): A final "golden sample" made with all actual bulk materials and trims. Your formal approval of the PPS is required to begin mass production.

This collaborative sampling process ensures the final product perfectly matches your vision and quality standards.

Step 3: Mass Production and Delivery Logistics

With the PPS approved and the purchase order confirmed (typically with a deposit), we launch full-scale production.

- Mass Production: Our production planning team schedules your order, and our QC team monitors the entire process, from fabric cutting to final assembly, ensuring adherence to the approved sample and your AQL standards. We maintain open communication, providing you with progress updates along the way.

- Final Inspection: Once production is complete, a final quality audit is conducted. We welcome you to send your own third-party inspection agent to our facility for this audit, or we can provide you with our detailed internal report.

- Logistics & Shipment: After the final inspection is passed and the balance payment is settled, our logistics team manages the final leg of the journey. We work with your designated freight forwarder or manage the entire process ourselves, depending on the agreed-upon Incoterms (FOB, CIF, or DDP). We handle all export documentation to ensure a smooth departure, providing you with the necessary shipping documents to clear customs upon arrival.

This final step completes a seamless, end-to-end process, delivering your high-quality, custom rainwear on time and to your exact specifications.

Why Partner With Us for Your Wholesale Raincoat Needs?

Choosing a manufacturing partner is one of the most critical decisions your business will make. It’s a choice that directly impacts your product quality, brand reputation, supply chain reliability, and ultimately, your bottom line. In a crowded global market, we distinguish ourselves by being more than just a factory; we are a strategic partner invested in your success. Our entire operation is built on three pillars: unparalleled expertise, direct-from-source efficiency, and dedicated, transparent partnership. We combine the cost advantages of large-scale production with the meticulous care and specialized knowledge of a niche workshop. This unique value proposition is designed to provide you with a secure, efficient, and profitable sourcing solution that empowers your brand to thrive. When you partner with us, you are not just placing an order; you are leveraging a robust manufacturing ecosystem built for the specific challenges of waterproof apparel.

Decades of Specialized Waterproof Apparel Experience

Our core strength lies in our specialization. Unlike generalist garment factories, we have dedicated decades to mastering the specific science and craft of manufacturing high-quality waterproof and plus-size apparel. This is not a sideline for us; it is our entire focus. Our teams—from pattern makers to sewing line operators—possess a deep, institutional knowledge of how to work with technical fabrics, how to properly execute seam sealing for guaranteed waterproofness, and how to grade patterns for a superior plus-size fit. We have already navigated the steep learning curve associated with these complex categories. This accumulated experience translates into faster problem-solving, more innovative product development, higher quality consistency, and a significant reduction in production risks for your business. You benefit directly from our years of trial, error, and refinement, gaining access to a proven system of excellence from day one.

Direct-from-Factory Pricing & Cost Efficiency

By partnering with us, you eliminate the layers of agents, trading companies, and other intermediaries that add unnecessary costs and communication delays. You are engaging directly with the source of production. This direct-to-factory model provides two significant advantages. Firstly, it ensures maximum cost efficiency. Our quotations are transparent and reflect the true cost of production, allowing you to achieve healthier profit margins or offer more competitive pricing to your customers. Secondly, it creates a direct line of communication between your technical team and our production managers. This eliminates the "broken telephone" effect, ensuring that your specifications are understood perfectly and that feedback is implemented quickly and accurately. This streamlined communication and pricing structure creates a more efficient, responsive, and profitable supply chain for your brand.

Dedicated Project Management & English-Speaking Support

We understand that clear, timely, and professional communication is the bedrock of a successful international business relationship. To ensure a seamless experience, every client is assigned a dedicated, English-speaking Project Manager. This individual serves as your single point of contact within our organization, responsible for guiding your project from initial quotation to final shipment. Your Project Manager is a trained professional who understands both your commercial needs and our factory’s operational capabilities. They are responsible for providing regular updates, managing the sample approval process, answering your questions promptly, and proactively resolving any issues that may arise. This dedicated support system removes the friction and uncertainty often associated with overseas manufacturing, providing you with the peace of mind that comes from knowing a professional advocate is managing every detail of your order on the ground.

Frequently Asked Questions (FAQ) for B2B Buyers

Our MOQ typically starts at 3000 to 5,000 units per style, per color. However, this can vary depending on the complexity of the design and the specific fabric chosen, as fabric mills have their own minimums. For highly specialized materials or complex designs, the MOQ may be higher. We encourage you to discuss your needs with us, as we can sometimes offer solutions for smaller quantities, especially for ongoing programs.

Yes, absolutely. Precise color matching is a core part of our service. For a specified MOQ, we can custom-dye fabric to match your specific Pantone (PMS) code. For this process, we will produce “lab dips” (small swatches of dyed fabric) for your approval before proceeding with bulk fabric production.

For the best results, we require vector-based files, such as Adobe Illustrator (`.ai`), Encapsulated PostScript (`.eps`), or Portable Document Format (`.pdf`). Vector files allow us to scale your logo to any size without losing quality, ensuring a crisp and clean finish for screen printing or heat transfer applications.

We have a multi-stage sampling process (Proto, Fit, Pre-Production). There is typically a sampling fee, which covers the cost of pattern making, materials, and labor for these initial units. This fee is often credited back to you or waived upon placement of a bulk production order that meets a certain value. The lead time for initial samples is generally 2-4 weeks.

We guarantee waterproofness through a combination of three key elements:

- Material Selection: We use fabrics with certified waterproof coatings (PU, TPU) or membranes with specific hydrostatic head ratings (e.g., 5,000mm, 10,000mm).

- Seam Sealing: All critical seams are sealed from the inside with waterproof tape using specialized heat and pressure machines. This prevents water from penetrating the stitch holes.

- Testing: We can provide third-party lab test reports (e.g., from SGS, Intertek) that certify the waterproof performance of both the fabric and the finished garment.

AQL stands for Acceptable Quality Limit. It is a statistical method used to determine the number of units to inspect from a production lot and the maximum number of defects allowed for the lot to be considered “accepted.” Our factory standard is typically AQL 2.5 Major / 4.0 Minor, which is a widely accepted standard in the apparel industry. We can also work to a stricter AQL level if required by your company’s quality standards.

Yes, we welcome and encourage it. We are fully transparent in our production and quality processes. You can arrange for your own inspector or a third-party agency (like SGS, Intertek, QIMA, etc.) to conduct an in-line or final pre-shipment inspection at our facility. We will provide them with the necessary access and support.

We are flexible and can work with a variety of Incoterms to suit your logistical needs:

- FOB (Free On Board): We handle everything until the goods are loaded onto the ship at the port of departure in China. You manage the ocean freight and destination logistics. This is the most common term.

- CIF (Cost, Insurance, and Freight): We manage and pay for shipping and insurance to your destination port. You handle customs clearance and inland delivery.

- DDP (Delivered Duty Paid): We manage the entire process door-to-door, including shipping, insurance, customs clearance, and payment of duties/taxes. The goods arrive at your warehouse without any further logistical hassle for you.

- Production Lead Time: After the pre-production sample is approved and the deposit is received, mass production typically takes between 40 to 90 days, depending on the order quantity and complexity.

- Shipping Lead Time: Ocean freight transit time varies by destination. For example, shipping from Shanghai to the US West Coast is approximately 15-30 days, while shipping to the US East Coast or Europe is approximately 30-60 days. Air freight is much faster (5-10 days) but significantly more expensive.

Our standard payment terms for new clients are a 50% deposit to confirm the order and begin production, with the 50% balance payment due upon completion of the goods, typically after the final inspection has been passed and before the goods are shipped (e.g., against a copy of the Bill of Lading). For long-term partners with a strong payment history, we can discuss more flexible terms.

Absolutely. We operate with the highest level of integrity and discretion. Protecting our clients’ intellectual property is fundamental to our business model. We are more than willing to sign a Non-Disclosure Agreement (NDA) before you share any sensitive design information. As an OEM/ODM partner, our success depends on your success, and we treat your designs as confidential information.

Initiate Your Bulk Plus Size Raincoat Project Today

Take the next step in creating a successful waterproof apparel line. Our team is ready to help you translate your vision into a high-quality, market-ready product. Whether you have a complete technical package or are just beginning with a concept, we have the expertise and infrastructure to support your goals. Partner with a manufacturer that understands the nuances of technical fabrics, the importance of a perfect plus-size fit, and the demands of the global supply chain. Let us show you how our specialized experience and direct-from-factory model can become a competitive advantage for your brand. Choose one of the options below to get started.