Your Premier Private Label Raincoat Manufacturer for EU REACH Markets

Partner with a leading private label raincoat manufacturer specializing in the design, development, and high-volume production of fully custom, EU REACH compliant rainwear. We are the strategic sourcing partner for global brands, promotional agencies, and industrial suppliers seeking uncompromising quality, transparent collaboration, and a secure supply chain into the European Union. Our expertise in advanced material science, rigorous compliance protocols, and end-to-end OEM/ODM solutions makes us the definitive choice for your next rainwear collection. We transform your vision into market-ready products that protect your customers and your brand reputation.

Advanced Material Science: From Polyester to Eco-Friendly TPU Raincoats

Attention: The material you choose defines your product’s performance, price point, and compliance standing. In the competitive rainwear market, a deep understanding of fabric science is not a luxury—it’s a necessity for creating products that resonate with your target audience and meet stringent regulatory demands. As your manufacturing partner, we provide expert guidance through the complex landscape of technical textiles, ensuring your choice is a strategic one. We go beyond surface-level specifications to analyze the molecular composition, performance characteristics, and environmental impact of each option, empowering you to make the most informed decision for your brand.

: Choosing the Right Fabric: A Comparison of PE, PEVA, EVA, and PVC

- PE (Polyethylene): The most cost-effective option, PE is ideal for high-volume, disposable ponchos used at sporting events, theme parks, or outdoor festivals. It offers basic waterproof protection at an unbeatable price point.

- PVC (Polyvinyl Chloride): Historically popular for its durability and excellent water resistance, PVC provides a classic, robust feel. Its primary challenge is EU REACH compliance. We only utilize phthalate-free PVC formulations that are rigorously tested to meet all REACH requirements.

- PEVA (Polyethylene Vinyl Acetate) & EVA (Ethylene Vinyl Acetate): These materials represent the modern, eco-conscious evolution of polymer rainwear. Both are chlorine-free and phthalate-free, offering a significantly softer, more pliable hand-feel and better cold-weather performance.

Our role is to demystify these options. We provide physical samples, detailed technical data sheets, and compliance certificates, allowing your team to feel the difference and understand the technical and commercial implications of each choice.

The Performance Benefits of Polyester, Nylon, and Oxford Fabric Rainwear

When moving from disposable ponchos to durable, retail-ready rain jackets, the focus shifts to woven technical fabrics like polyester, nylon, and Oxford cloth. Polyester offers an exceptional balance of durability, water resistance, and cost-effectiveness. Nylon is renowned for its superior strength-to-weight ratio. Oxford fabric is an exceptionally durable weave, perfect for workwear and rugged gear.

Sustainable Innovation: The Rise of TPU in REACH Compliant Rainwear

At the pinnacle of modern rainwear materials is TPU (Thermoplastic Polyurethane). It represents the convergence of high performance, sustainability, and absolute compliance. TPU offers superior elasticity, abrasion resistance, and is inherently free from plasticizers and phthalates, making it the strategic choice for premium and eco-conscious brands targeting the discerning EU market.

Guaranteeing Compliance: Our Unwavering Commitment to EU REACH Standards

Attention: In the European Union, compliance is not optional—it is the price of market entry. For a brand sourcing rainwear, a single shipment failing to meet EU REACH regulations can lead to catastrophic consequences: rejected imports, forced product recalls, significant financial penalties, and irreversible damage to your brand’s reputation. We don’t just produce rainwear; we deliver peace of mind.

What is EU REACH and Why It's Critical for Your Rainwear Brand

REACH is a comprehensive EU regulation designed to protect human health and the environment from chemical risks. For rainwear, it governs product safety and market access. Key aspects include managing Substances of Very High Concern (SVHCs) and adhering to the list of Restricted Substances. Non-compliance leads to seized shipments, legal fines, and severe brand damage.

Our Internal Testing & Third-Party Verification for REACH Certification

Our three-pillar verification process guarantees compliance: 1. Rigorous raw material vetting with supplier Certificates of Conformity. 2. In-process quality control to prevent unauthorized chemical use. 3. Independent third-party laboratory testing (SGS, Intertek) of finished products against the latest SVHC list. You receive a full documentation package, including the lab report, as your ‘passport’ for the EU market.

Navigating SVHCs (Substances of Very High Concern) in Textile Manufacturing

We proactively monitor ECHA updates to manage SVHCs. For example, we use only phthalate-free PVC to eliminate risks associated with common plasticizers like DEHP. We also mandate the use of APEO-free detergents and ensure all dyes are free from restricted azo colorants. Our transparent, collaborative approach empowers your brand to be compliant and confidently articulate your commitment to safety.

Your Vision, Our Expertise: The Seamless Private Label & OEM Rainwear Process

Attention: Transforming a design concept into a successful, market-ready product line requires more than just machinery; it demands a structured, transparent, and collaborative process. As a premier private label rainwear manufacturer, we function as an extension of your own team, guiding you through each critical stage from initial idea to bulk production.

Step 1: Design Consultation and Digital Prototyping

Our process begins with a deep-dive consultation to understand your vision. We analyze your requirements, provide expert recommendations on materials, and use CAD software to create detailed digital mock-ups. This ensures a shared, precise understanding of the final product before any physical resources are committed.

Step 2: Private Label Polyester Raincoats EU Material Sourcing and Sampling

We move to physical validation by sourcing the exact fabrics from our pre-vetted, compliant suppliers. We produce ‘lab dips’ for color approval and create a full Pre-Production Sample (PPS). You receive this production-quality garment for final approval, giving you complete authority over the final product before bulk manufacturing begins.

Step 3: Full-Scale Production and Quality Control Checkpoints

Upon PPS approval, we launch full-scale manufacturing. Our process is defined by rigorous, multi-stage quality control, from automated cutting to in-line inspections and a final audit based on the AQL standard. This meticulous approach ensures every garment meets your quality standards.

A Reliable EU Supply Chain: Your Trusted Wholesale Raincoats EU Supplier

Attention: Manufacturing a superior product is only half the battle. Getting that product to your warehouse in the EU on time, on budget, and without customs complications is just as critical. We have architected a robust and transparent supply chain designed specifically for the complexities of the EU market. We don’t just ship boxes; we manage a seamless flow of goods from our factory floor to your doorstep.

Optimized Logistics for Fast, Cost-Effective Delivery Across Europe

We offer flexible Incoterms (FOB, CIF, DDP) and multi-modal freight solutions (sea, air, rail) to optimize your timeline and budget. For smaller volumes, we provide LCL consolidation services. Our logistics team provides proactive tracking and communication throughout the process, giving you full visibility.

Managing Tariffs, Customs, and Importation into the EU Market

Our dedicated customs department ensures smooth importation. We handle accurate HS code classification to determine correct import duties and prepare a complete, error-free set of customs documents, including the crucial Certificate of Origin and REACH compliance reports, to prevent any delays at port of entry.

Our Warehousing and B2B Nylon Raincoat Supplier Europe Distribution Network

For brands needing end-to-end solutions, we offer EU-based warehousing and distribution. We can manage your inventory, and provide B2B pick-and-pack fulfillment services. This ‘virtual warehouse’ model allows you to serve the European market with the speed and efficiency of a local company without the overhead.

Uncompromising Quality: Our Raincoat Factory Europe Testing & QA Protocols

Attention: In the world of performance rainwear, quality is not a subjective feeling—it is a measurable, verifiable science. We have embedded a culture of empirical testing and rigorous quality assurance into every stage of our process. We don’t just promise quality; we prove it with data.

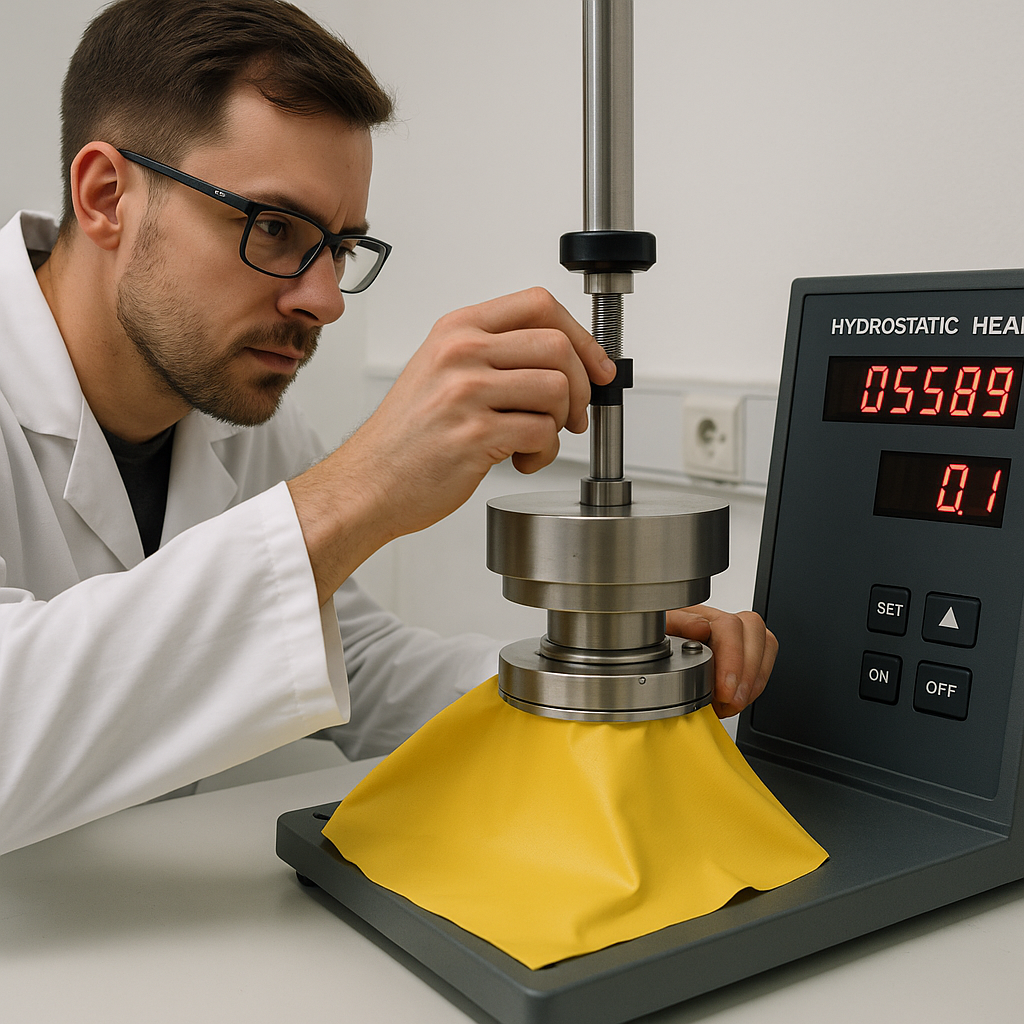

Hydrostatic Head Testing for Absolute Waterproofing Assurance

We quantify waterproofness using the ISO 811 Hydrostatic Head (HH) test. This measures the water pressure a fabric can withstand before leaking. We verify HH ratings on incoming fabric and on finished garments, providing you with official test reports to confidently market your product’s performance from 1,500mm to over 20,000mm.

Seam Sealing Integrity and Garment Durability Stress Tests

A raincoat is only as waterproof as its seams. We use advanced seam sealing machines to apply waterproof tape over every stitch line, and ultrasonic welding for polymer goods. We conduct tape peel tests, pressurized water tests on seams, and a battery of durability tests (tensile strength, abrasion resistance) to ensure long-term performance.

AQL (Acceptable Quality Limit) Inspections Before Final Shipment

As the final gatekeeper of quality, we conduct pre-shipment audits using the AQL statistical sampling method (ISO 2859-1). An independent QC team inspects a random sample for critical, major, and minor defects. If the batch fails, it is held for 100% re-inspection and rework. We provide you with the full, transparent AQL report before shipment.

Custom Logo Raincoats Bulk: End-to-End Brand Customization Options

Attention: A private label raincoat is a wearable billboard for your brand. We specialize in transforming generic rainwear into unique, branded assets through a comprehensive suite of customization options, realizing your brand’s aesthetic vision down to the smallest detail.

Advanced Logo Application: Screen Printing, Embroidery, and Heat Transfer

We offer expert guidance on choosing the best logo application. Screen printing for bold designs, heat transfer for complex multi-color logos, and premium embroidery for a classic, high-value look. For performance wear, we seal the back of all embroidery to maintain waterproof integrity.

Customizing Colors (Pantone Matching), Zippers, Buttons, and Hardware

True private label manufacturing means controlling every component. We can dye fabric to any Pantone (PMS) color code, and source custom zippers, pulls, snaps, and drawcords—all branded or color-matched to create a product that is uniquely yours and stands out from off-the-shelf alternatives.

Bespoke Packaging and Labeling for a Retail-Ready Product

The customer experience begins with the presentation. We manage all aspects of packaging and labeling, from high-definition woven neck labels and custom hangtags to branded polybags, fabric pouches, and retail boxes. We ensure every element is aligned with your brand standards, delivering a product that’s ready to sell the moment it arrives.

Industry-Specific Solutions: From Promotional Plastic Ponchos to Corporate Rainwear

Attention: Not all rainwear is created equal. A disposable poncho serves a different purpose than a high-visibility work jacket. We have developed specialized expertise and production lines to cater to the unique demands of diverse industries. We engineer industry-specific products that solve your specific challenges.

High-Volume Vinyl Rain Poncho Supplier for Events and Festivals

For events, we provide cost-effective, high-visibility PE and PEVA ponchos. We handle massive order volumes with significant economies of scale, and our high-speed production and screen-printing are optimized for large, bold logos. We manage event-driven deadlines to ensure your compliant, branded ponchos arrive on time.

Durable, Branded Rain Jackets for Corporate, Industrial, and Workwear

For workforces, we prioritize durability, safety, and function. We use robust materials like heavy-duty Oxford fabric and integrate features like EN ISO 20471 high-visibility compliance, radio loops, and helmet-compatible hoods. Durable embroidery or heat transfers ensure a professional, lasting brand image.

Retail-Ready Fashion Rainwear for Private Label Apparel Brands

For fashion brands, aesthetics are paramount. We translate designer visions into retail products, sourcing trend-focused materials like high-gloss TPU or recycled fabrics. Our pattern makers perfect contemporary fits, and we excel at high-end finishing touches like custom hardware and intricate stitching that signify quality to the discerning customer.

The Partnership Advantage: Why Sourcing With Us is a Strategic Decision

Attention: A truly strategic sourcing decision is not about finding a supplier; it’s about finding a partner. We are structured to be that partner. Choosing us means investing in a relationship built on transparency, dedicated support, and a shared commitment to your long-term success. We provide a competitive advantage.

Dedicated Account Management and Direct-from-Factory Technical Support

You are assigned a dedicated, English-fluent Account Manager as your single point of contact. They provide seamless communication, proactive updates, and direct access to our in-house engineers and compliance specialists. This structure ensures a responsive experience, making complex manufacturing feel simple and secure.

Transparent Pricing and Flexible MOQ for Find PE Raincoat Manufacturer Bulk Order

We provide clear, itemized quotations and a tiered pricing structure that rewards volume. Our flexible MOQs are designed to support emerging brands and new product launches. We work with you to find solutions, like using stock materials for smaller initial orders. Our goal is to grow with you.

Long-Term Product Development and Innovation Collaboration

We evolve from a supplier into an innovation partner. We share our R&D on new materials and techniques, offer trend forecasting, and collaborate on continuous product improvement. This commitment to innovation means your product gets better with every order, securing your long-term success.

Sustainable Sourcing: Your Partner for Eco-Conscious Rainwear

Attention: Sustainability has evolved from a niche interest into a core business imperative. Sourcing eco-conscious products is good for your brand, your market position, and your bottom line. We have integrated sustainable practices and materials into the heart of our operations, enabling you to build a rainwear line that aligns with modern values.

Benefits of PEVA Raincoats Wholesale Europe as a PVC-Free Alternative

PEVA is the leading PVC-free solution. Its chlorine-free composition and lack of harmful plasticizers make it a cleaner, safer material that simplifies REACH compliance. It’s also softer, lighter, and more flexible than PVC, creating a better product with a powerful ‘PVC-Free’ marketing claim.

Recycled Polyester (rPET) and Bio-Based TPU Material Options

We offer cutting-edge sustainable textiles. GRS-certified Recycled Polyester (rPET) is made from post-consumer plastic bottles, saving energy and diverting waste from landfills. Bio-Based TPU replaces a portion of fossil fuels with renewable, plant-based feedstocks, reducing your product’s carbon footprint without compromising performance.

Our Commitment to Reducing Waste in the Manufacturing Lifecycle

Sustainability is about process. We use advanced CAD nesting and automated cutting to maximize fabric yield and reduce waste. We partner with dye houses that use water-recycling plants, and we operate a rigorous waste segregation and recycling program within our own factory to minimize our environmental footprint.

Advanced Manufacturing: How We Engineer Superior Waterproof Jacket Manufacturer Private Label Products

Attention: A superior raincoat is engineered, not just assembled. The difference lies in the precision, technology, and advanced techniques used in its construction. We invest in cutting-edge machinery and cultivate deep technical expertise to create garments that offer superior performance, durability, and a refined aesthetic.

High-Frequency Ultrasonic Welding vs. Stitched & Taped Seams

We offer both classic stitched-and-taped seams for versatility and advanced high-frequency ultrasonic welding for polymer materials (TPU, PVC, EVA). Ultrasonic welding creates a stitchless, 100% waterproof bond that is flat, strong, and provides a sleek, modern aesthetic ideal for premium garments.

Precision Laser Cutting for Material Efficiency and Complex Designs

We utilize state-of-the-art laser cutting technology for unmatched precision. A computer-guided laser cuts fabric with perfect accuracy, ensuring every pattern piece is identical. For synthetics, it also seals the fabric edge to prevent fraying, enabling complex designs and maximizing material efficiency.

Multi-Layer Fabric Lamination for Breathable Waterproof Performance

We achieve waterproof/breathable performance through advanced fabric lamination. We bond high-performance micro-porous membranes (like TPU) to face fabrics to create 2-Layer, 3-Layer, and lightweight 2.5-Layer composites. This technology blocks rain while allowing sweat vapor to escape, and is the core of true performance rainwear.

Transparent B2B Pricing for Wholesale Raincoats EU

Attention: We believe in a transparent, collaborative approach to pricing. Our goal is to provide you with a clear, predictable, and competitive cost structure that allows you to plan, budget, and scale your business with confidence. We don’t just give you a price; we show you the value behind it.

Understanding Our Tiered Pricing Structure for Bulk Orders

We leverage economies of scale with a tiered pricing structure that provides clear cost reductions as your order volume increases. Our quotations clearly outline the per-unit cost at different volume thresholds, allowing your purchasing team to make strategic decisions and precisely calculate the ROI of increasing an order quantity.

Key Factors Influencing Your Final Per-Unit Cost

We provide transparency on cost drivers. The final price is influenced by material selection, fabric consumption, construction complexity, customization level, order quantity (MOQ), and required compliance testing. Understanding these variables empowers us to work together to engineer a product that meets your quality standards and financial targets.

How to Request a Detailed, No-Obligation Project Quotation

To receive a fast, accurate quote, provide us with as much detail as possible: a technical pack, design files, material specifications, estimated order quantity, and customization details. Sharing a target cost is also helpful. Our team will analyze your request and return a comprehensive, itemized quotation within 2-3 business days.

Client Success Story: Launching a REACH Compliant TPU Rain Jacket Factory Line

Attention: Theory and promises are important, but proven results are what truly matter. This case study illustrates how we partnered with a mid-sized European fashion retailer to overcome significant sourcing challenges and successfully launch a premium, compliant, and profitable rainwear collection.

The Challenge: An EU Retailer Required Certified, Fashion-Forward Rain Jackets

A European fashion retailer needed a line of minimalist TPU rain jackets but had faced compliance failures and poor quality from previous suppliers. They required a partner who could produce an aesthetically superior product with an ironclad guarantee of EU REACH compliance on a tight deadline.

Our Solution: Custom-Designed TPU Jackets with Full REACH Documentation

We implemented our structured partnership process: a deep-dive consultation, selection of a premium frosted TPU, and engineering the design with ultrasonic welding for a seamless look. We provided rapid sampling and proactively sent materials for independent SGS lab testing, ensuring full transparency throughout production.

The Result: Successful Market Launch and a 30% Increase in Seasonal Sales

The order was delivered on-time with full REACH documentation, clearing customs without issue. The line was a commercial hit, resulting in a 30% increase in seasonal sales for the category. The client was highly satisfied, and we have become their strategic partner for their entire outerwear collection.

FAQ: Your B2B Rainwear Sourcing Questions Answered

Our MOQ is flexible and depends on the product. General guidelines:

- Promotional Ponchos (PE/PEVA): Starts at 5,000 – 10,000 units.

- Fabric Raincoats (Polyester/Nylon): Standard MOQ is 1,000 units per style/color.

- Premium Materials (TPU/Laminated): MOQs typically start around 1,000 – 2,000 units.

We are committed to finding solutions for smaller quantities, such as using in-stock fabric colors. Please contact our specialists to discuss your needs.

Our non-negotiable protocol includes: 1. Vetting suppliers for their own compliance declarations. 2. Internal risk assessments of all product components. 3. Submitting finished products to accredited third-party labs (SGS, Intertek) for full screening against the latest SVHC list. 4. Providing you with a complete documentation package, including the official lab report, to guarantee customs clearance.

The important is that : Pls inform your exactly request of standard before offer, and You test the samples before bulk production, so can sure all materials satisfied of your request standard.

A typical total lead time from final sample approval to delivery in Europe via sea freight is approximately 75-100 days. This breaks down into:

- Production Lead Time: 45-90 days, depending on order size and complexity.

- Shipping Lead Time: Approximately 30-40 days for sea freight, plus customs clearance.

Faster options like rail (20-25 days) and air freight (5-10 days) are available for time-critical shipments.

Absolutely. We are completely flexible and highly experienced in working on an FOB (Free on Board) basis. We will manage all production and quality control, and coordinate a seamless handover of all cargo and documentation to your designated freight forwarder at the port of origin.